How much it cost

How much material you will spend if you produce the windows from our products and of course β how much money it will costs you?

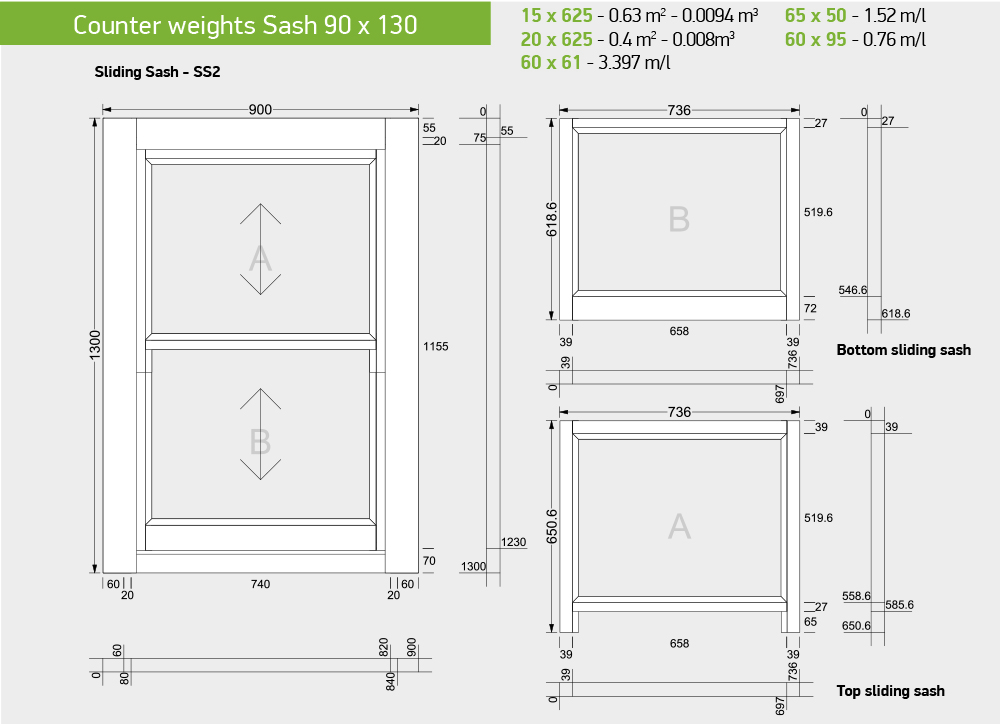

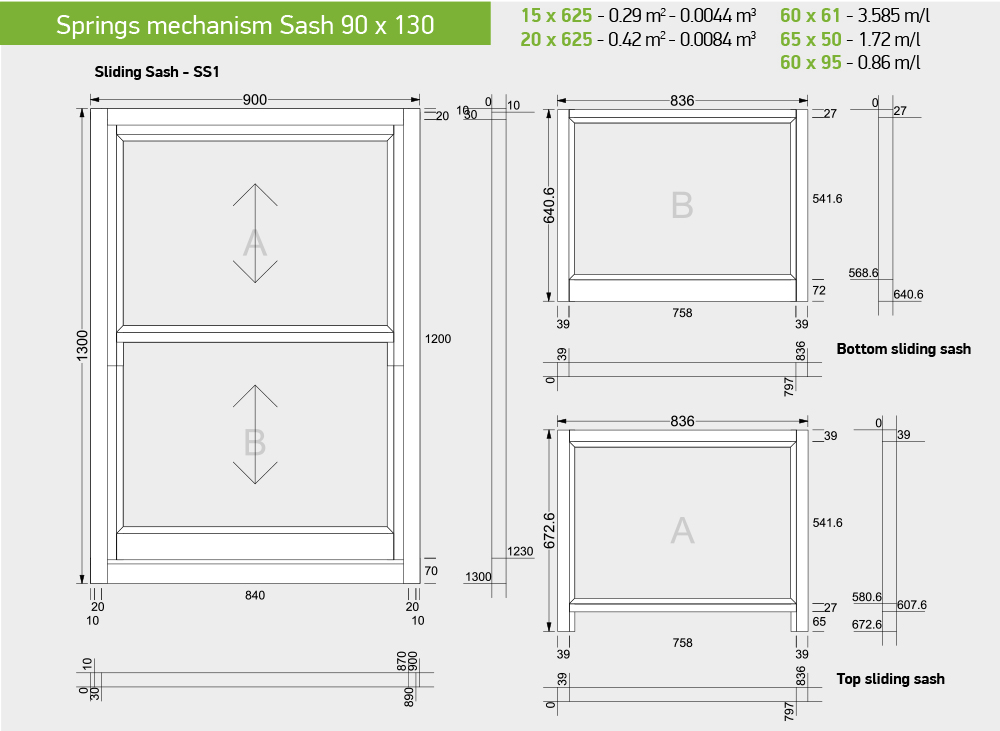

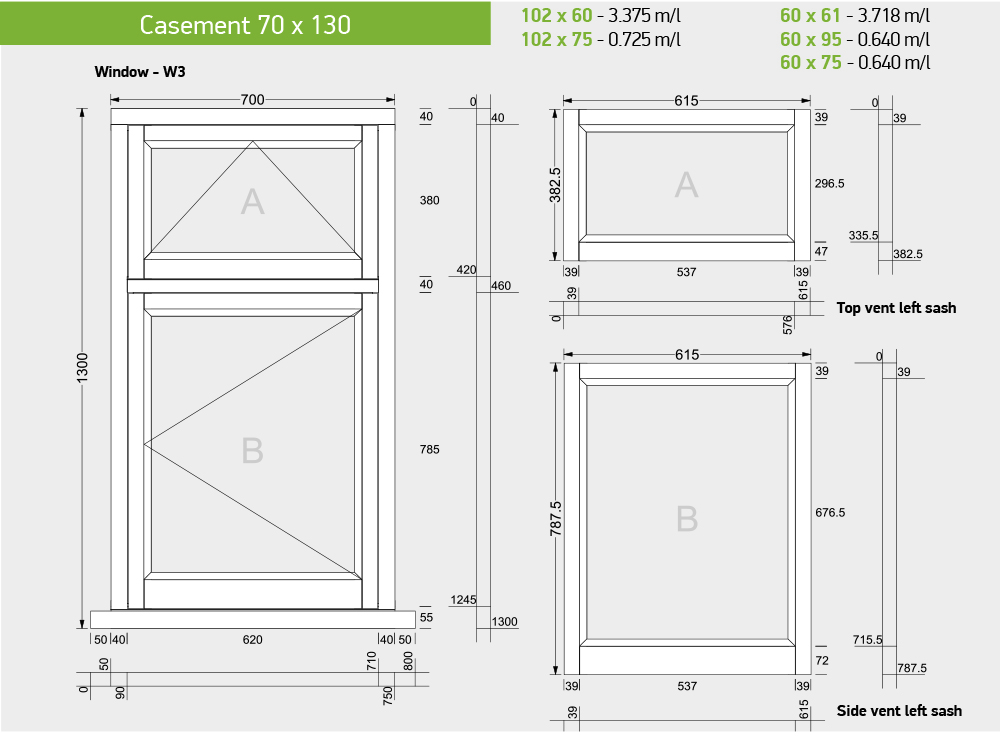

When we prepared our stand for Timber Expo 2016 in NEC Birmingham we have ordered to one of our customers to produce for us several different basic types Traditional UK windows just to show at our stand how our products are used in windows production. What you can see bellow is their unedited report of how much material from each size they have used (including waste and leftovers!) to produce the real windows which you can see at our stand. Since we have issued to them a credit note for these volumes β we believe they have made correct calculation.

In total = avg. 0,0364 m3 per window including the waste and leftovers

When you use our products to manufacture a.m. windows β total cost of the wood material spend (including the waste and delivery) will vary from 35 EUR to 90 EUR per window (depending from the different wood species you choose and the volume of you order). Thatβs it β no strings attached, no hidden costs and no small size letters at the bottom.

For comparison β if you have to produce the same windows from 1β, 2β, 2.5β, 3β etc sawn timber the volume of wood you spend will be min. 0,100 m3 (including waste) per window. But You already know that β donβt you?

Not to mention that when you profile the window details from sawn timber it is not rare case when the window details become twisted almost immediately after they come out of the machine.

How is that possible?

Well, we deliver our products in 6,00 m lengths regardless of the cross section β therefore you will have negligible waste in the lengths cutting. Whatever is left from one window is used in the next one depending from the windows size. The cross sections of our engeneered wood scantlings are designed as close as possible to the finish size of your window profile.

And last but not least, when you use our engineered laminated panel boards to produce the box (which hide the counter weights or springs) of the sash windows β itβs much easier and you donβt have to drill the sawn timber (if you use the 3β timber) or you donβt waste 30-40% on planning down (if you use 1β timber). We deliver the panel boards in 625 mm widths β so you have practically no waste when you cut the box details whatever the wall/window thickness is required.

Additionally, when you use our products for you windows production (instead of sawn timber) β you are saving the labor costs for cutting the timber to necessary dimensions (as you know β no machine can do that job). And because the overall volume of the wastage and leftovers from you production is more then x 5 times less compared when you used the sawn timber β you will have to pay much less for the waste collection from you factory.